Cement Works

In 1921, a Sheffield builder called Frank Walker bought 1174 acres of Ketton parish, most of which consisted of old quarries and clay pits, to build a cement works on. In 1925 he established a small concrete block factory company under the name "Walkers Ketton Stone Company", and by 1927 was looking to raise the capital for a cement works. The project was taken up by Sheffield businessmen Joseph and Thomas Ward.

Frank Walker sold his business to the newly formed Ketton Portland Cement Company in July 1928, followed by his land at Ketton in August. Work began on the cement works on 1 August 1928, with much of the machinery and railway equipment coming from Wards. The first full weekly wage-bill of £202.2.11 was paid on the week ending 10 August 1928 for about 90 men. By the week ending 8 November, the wage bill had risen to over £600 for around 250 men and boys, which were at work on the site.

One of the initial factors in the location of the plant, other than the high quality of lime and silica clays present onsite, was the proximity of the LMS Birmingham to Peterborough Line to the south of the factory. In 1928 Ketton Cement Works had its own rail siding (known as "Wards Sidings") which enabled it to receive and dispatch train loads of cement while receiving fuel into the plant.

During the Second World War, the demand for cement increased hugely due to the construction of military bases and defences, but, as wіth most industry at the time, Ketton Cement suffered hugely from labour shortages due to the call up of most able-bodied men. Further growth continued into the 1960s as the mass slum clearances lead to mass redevelopment in towns and cities.

The rail siding closed in 1963. Kilns 1-4 were closed in 1986 followed by Kilns 5-6 in 1987. These have now been demolished and the area where they stood now grassed over. Only Kilns 7 and 8 still stand.

In 1981, Thomas W Ward company became part of Rio Tinto Zinc [RTZ] and Ketton Cement was rebranded as Castle Cement. In 1989 Castle Cement passed into the ownership of Scancem until they were bought by Heidelberg Cement in 1999. In 2007 Hanson Plc was bought by Heidelberg and became Hanson Cement.

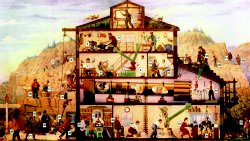

This is the cement age. Roads, bridges, buildings and harbours are being poured out in liquid form all over the country. It is because of this that Thomas W. Ward, the most versatile company in the engineering world, it taking a controlling interest in a new company at Ketton Village Historyshire. Wherever engineering is done Ward's are known. They are constructional engineers and will sell you anything from a nut and bolt to a whole works. At the same time if you have a derelict works, an old battleship, or an out-of-date liner to dispose of Ward's are the people to whom you turn. They own 32 separate works spread all over the country and have constructed them all themselves. Their staff is the school for experts. Every director is a worker. Whatever they buy they turn to some use. Worn machinery is reconditioned and with furniture, bricks and all the other debris of derelict mills, worked out collieries, or old and unwanted ships find a market. Even slag, the refuse of the steel and iron works, is turned to account by Ward's in its manufacture of road making material. Where there is no other use, every kind of metal material is turned into scrap for which there is a worldwide market and this is turned out by Ward's at the rate of 1,000 tons a week. The latest development, the establishment of Cement works and Ketton Stone at Ketton, is just filing up another corner in the completion of the company's immense business organisation. For 500 years Ketton Freestone has been in use in this country. Some of it is used in the Law Courts, York Minster, and other famous buildings all over the country. The quarries cover something like 1,100 acres. In addition to the freestone there is an almost illimitable quantify of Oolithic limestone called Ragstone. Some 2,000,000 tons of this is lying on the already quarried land with a similar amount of clay in big dumps and there is enough raw material to last 100 years even though it be used at a rate of 120,000 tons a year. Recent experiments have shown that this material is admirably suited for the manufacture of the best Portland Cement. Tests have demonstrated that for quality and capability of withstanding pressure it is unrivalled. Export reports have been made upon it with the most satisfactory results, and now the time has come to exploit it commercially. A new company has been formed with a capital of £300,000 in which Ward's have taken a controlling interest obtaining at the same time the sole selling agency for the new cement.